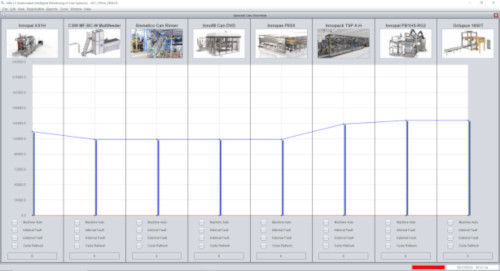

AIM-LS (Automated Intelligent Monitoring of Line Systems) is designed to revolutionize production line management, offering cutting-edge solutions for enhanced efficiency and reliability. Our system is built to empower industries by providing smarter, faster, and more adaptable manufacturing processes.

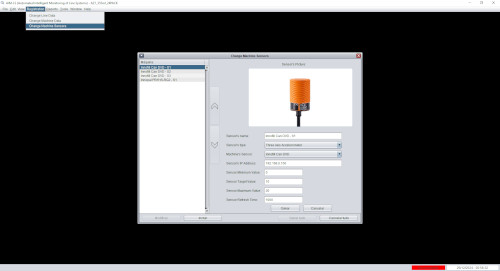

Stay ahead of production issues with live performance data. AIM-LS delivers real-time insights, allowing for rapid identification and resolution of inefficiencies, ensuring minimal downtime and maximum productivity.

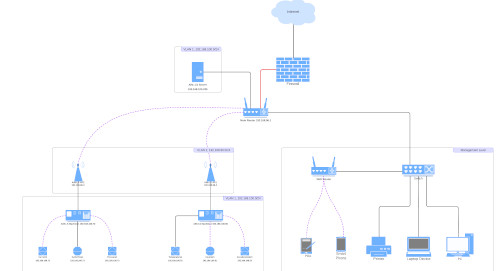

AIM-LS connects effortlessly with existing MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning) platforms. This ensures smooth communication between shop floor operations and upper management, streamlining workflows and enhancing decision-making processes.

Our system harnesses the power of AI and machine learning to predict equipment failures before they occur. By recommending preventive actions, AIM-LS reduces unexpected stoppages, prolongs equipment lifespan, and lowers maintenance costs.

AIM-LS grows with your business. Its modular architecture allows for easy expansion, adapting to new production demands and integrating emerging technologies without disrupting existing workflows.

For more information, contact us today and discover how AIM-LS can transform your manufacturing process.

Responsiveness

AIM-LS provides live insights into production performance, allowing quick identification of inefficiencies and immediate responses to minimize downtime, boosting productivity.

Connectivity

AIM-LS connects seamlessly with MES and ERP systems, ensuring data flow between the shop floor and management, improving planning, scheduling, and overall operational efficiency.

Reliability

Using AI and machine learning, AIM-LS predicts equipment failures and recommends preventive maintenance, reducing downtime and lowering operational costs.

Flexibility

Designed to grow with your business, AIM-LS is scalable and modular, allowing easy expansion and integration of new technologies to meet evolving production needs.

Lets get in touch and talk about your next project.